How can we help you?

Let us know how we can help you with your existing or future requirements. Just drop an email with your query, name and contact number and we will get back to you shortly.

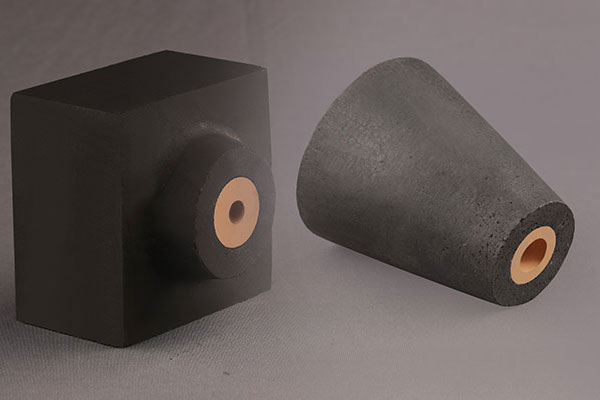

Refractory Division

sales@zirconiarefratech.com

zirconiarefractories@gmail.com

High Temperature Furnace Division

furnaces@zirconiarefratech.com